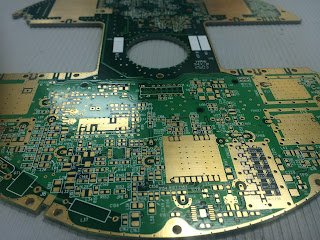

Crafting Tomorrow's Innovations: Pcb-Togo Electronic, Inc. - Your Flexible PCB Manufacturer

In the dynamic world of electronics, adaptability is the key to pushing the boundaries of innovation. Pcb-Togo Electronic, Inc. emerges as a beacon of flexibility with its state-of-the-art Flexible PCB manufacturing capabilities. As a leading player in the industry, Pcb-Togo Electronic, Inc. sets the stage for a new era of electronic design and functionality. Let's explore the world of Flexible PCBs and understand how this manufacturing marvel is reshaping the future of electronic applications. The Art and Science of Flexible PCB Manufacturing: Flexible Printed Circuit Boards (FPCBs) represent a departure from the rigidity of traditional circuit boards. Pcb-Togo Electronic, Inc. has perfected the art and science of Flexible PCB manufacturing, offering a range of solutions tailored to meet the diverse needs of modern electronic devices. What sets Flexible PCBs apart is their ability to conform to various shapes and contours, providing designers with unparalleled freedom in pro...