Factors To Look Into When Hiring Best PCB Supplier

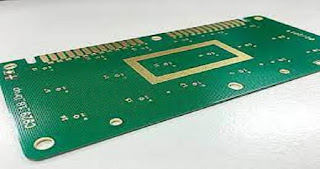

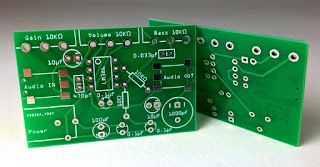

Electronic assembly cannot be complete without a good quality PCB. These are the boards that will mount the components together. A good quality board will reduce the need to use jumper wires across the circuit. The board that you use should have the best design so the size can be reduced. It should also support all electrical components so they do not fall out. The board will also allow the specific value of current to pass through each component. You need to look around for the best printed circuit board supplier . A good supplier will manufacture the best board. Factors you consider when selecting supplier There are many factors that you should consider when selecting a good supplier. 1. Capacity and expertise You may need hundreds of boards. You also need quality boards. This is why you have to focus on the capacity and expertise of the supplier. If you hire a new supplier, you may have to test his skills in advance. Focus on the price and lay